What is What is Tungsten Inert Gas (TIG) Welding?

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a precision welding process that utilizes a non-consumable tungsten electrode to produce the weld.

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a precision welding process that utilizes a non-consumable tungsten electrode to produce the weld. This method is renowned for its ability to create high-quality, clean welds on a wide range of metals, including stainless steel, aluminum, magnesium, and copper alloys.

How TIG Welding Works

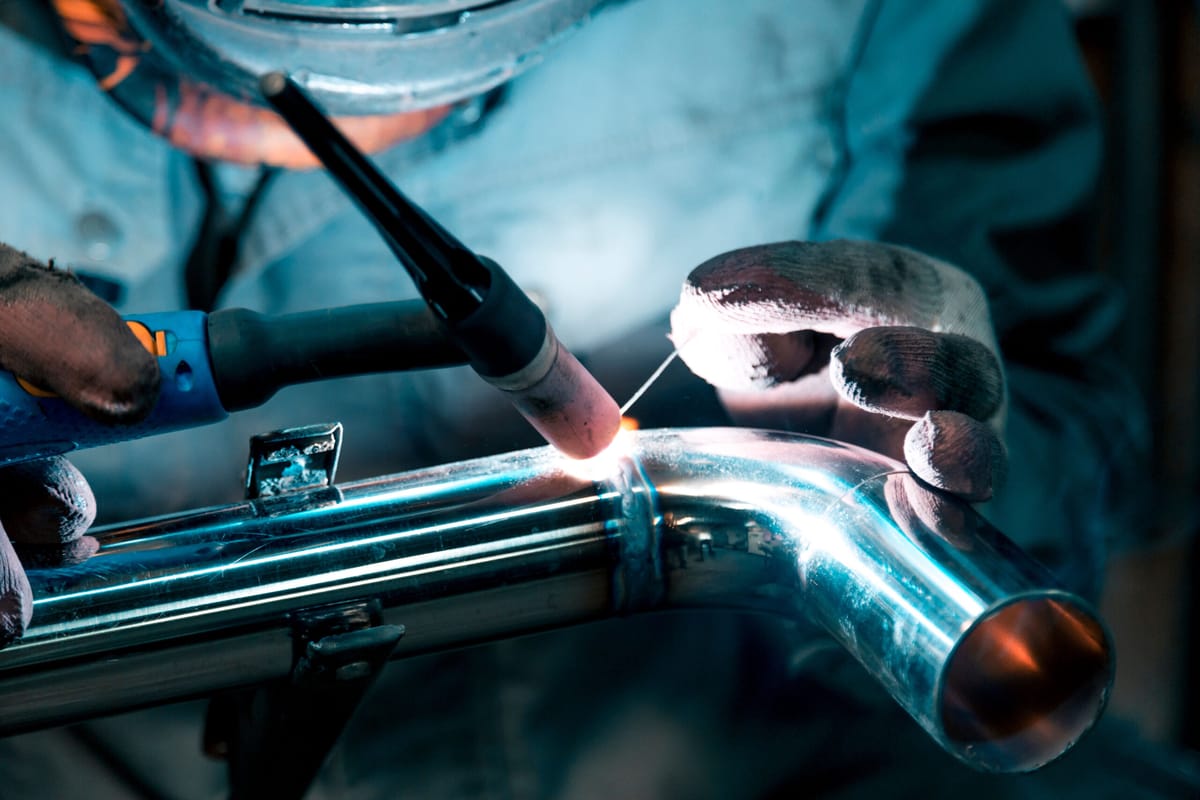

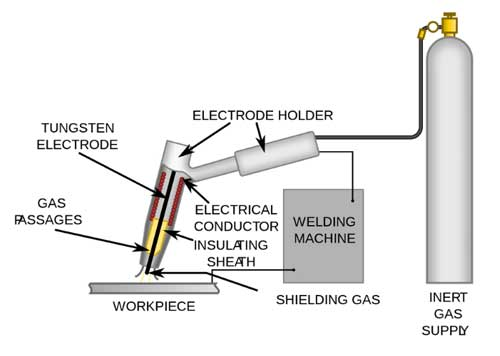

In TIG welding, an electric arc is formed between the tungsten electrode and the metal workpiece. The weld area is shielded from atmospheric contamination by an inert gas, typically argon or helium, which protects the molten weld pool from oxidation and impurities. A filler rod may be manually added to the weld pool if additional material is needed to complete the joint.

Advantages of TIG Welding

- High-Quality Welds: TIG welding produces clean, precise welds with minimal spatter and distortion.

- Versatility: It can be used to weld thin and thick materials and works well with a variety of metals.

- Control: Provides the welder with greater control over the welding process, allowing for detailed and intricate welds.

- No Flux Required: The inert gas shielding eliminates the need for flux, reducing slag and contamination.

Applications of TIG Welding

TIG welding is widely used in industries where precision and strength are crucial. Common applications include:

- Aerospace industry for aircraft components

- Automotive industry for custom exhausts and chassis fabrication

- Food and beverage industry for stainless steel piping

- Art and sculpture for decorative metalwork

TIG Welding Equipment

Basic TIG welding setup includes:

- Welding Machine: Provides the power supply for the arc.

- Tungsten Electrode: A non-consumable electrode that initiates the arc.

- Inert Gas Supply: Typically argon or helium gas cylinders with a regulator.

- Filler Rods: Optional, used for adding material to the weld.

- Protective Gear: Helmet, gloves, and protective clothing to safeguard against heat and UV radiation.

Conclusion

TIG welding is a versatile and precise welding technique suitable for high-quality and detailed work. Its ability to produce clean and strong welds makes it invaluable across multiple industries. Whether for industrial applications or artistic metalwork, mastering TIG welding opens the door to a wide array of welding opportunities.