What is Metal Inert Gas (MIG) Welding?

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is a welding process where a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining two base materials.

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is a welding process where a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining two base materials. The weld area is protected by a shielding gas that prevents contamination from atmospheric gases.

Brief History of MIG Welding

MIG welding was first developed in the 1940s for welding aluminum and non-ferrous metals. Over time, advancements in technology made it suitable for steel and other materials, making it popular in various industries today.

How MIG Welding Works

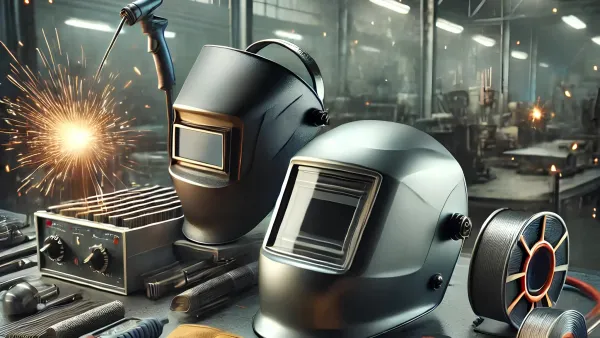

Basic Components of MIG Welding

- Welding Machine: Provides the electric current.

- Wire Electrode: Continuously feeds into the weld.

- Shielding Gas: Protects the weld from contamination.

- Welding Gun: Directs the electrode and gas flow.

The Welding Process Explained

The welding gun feeds the wire electrode into the weld joint while releasing shielding gas. An electric arc melts both the wire and the base material, forming a strong weld.

Key Equipment in MIG Welding

Welding Machine

Controls voltage and current, critical for welding quality.

Electrode Wire

Common materials include mild steel, stainless steel, and aluminum wires.

Shielding Gas

Inert or semi-inert gases like argon, CO₂, or a mix protect the weld pool.

Types of Shielding Gases

Argon

Ideal for welding aluminum and non-ferrous metals, producing a stable arc.

CO₂

Common for welding steel, offering deeper penetration but more spatter.

Argon-CO₂ Mix

Combines the benefits of both gases for cleaner and more efficient welds.

Advantages of MIG Welding

Ease of Use

MIG welding is user-friendly, making it great for beginners.

Versatility

Suitable for various metals like steel, aluminum, and stainless steel.

High Welding Speed

Faster than other methods, increasing productivity.

Disadvantages of MIG Welding

Limited Outdoor Use

Wind can blow away the shielding gas, causing weld defects.

Equipment Cost

Initial setup is more expensive than other welding methods.

MIG Welding vs. Other Methods

MIG vs. TIG Welding

MIG is faster and easier, while TIG offers more precision.

MIG vs. Stick Welding

MIG produces cleaner welds but is less effective outdoors.

Common Applications

Automotive Industry

Used for car body repairs and manufacturing.

Construction

Ideal for structural steelwork and frameworks.

Metal Fabrication

Perfect for creating metal parts and products.

Safety Precautions

Protective Gear

Wear welding helmets, gloves, and flame-resistant clothing.

Safe Workspace Setup

Ensure proper ventilation and a clutter-free area.

Tips for Beginners

Selecting the Right Settings

Adjust voltage and wire speed based on material thickness.

Common Mistakes to Avoid

Avoid poor gas flow and incorrect electrode angles.

Maintenance of MIG Equipment

Cleaning the Nozzle

Regularly remove spatter to maintain gas flow.

Checking the Wire Feed

Ensure smooth wire feeding to prevent welding defects.

Advanced MIG Techniques

Spray Transfer

A high-heat method producing smooth, strong welds.

Pulse MIG Welding

Alternates between high and low currents for better control.

Environmental Impact

Fume Emissions

Proper ventilation reduces exposure to harmful fumes.

Energy Consumption

MIG welding consumes more power than some alternatives.

Future of MIG Welding

Technological Innovations

Developments in automation and robotics are enhancing welding efficiency.

Automation in MIG Welding

Robotic MIG welders are now common in mass production.

Conclusion

MIG welding stands out for its versatility, speed, and ease of use, making it essential in industries like automotive, construction, and metal fabrication. While it has limitations like outdoor usability and higher initial costs, advancements in technology continue to improve its efficiency and application. Whether you're a beginner or an expert, understanding MIG welding can open doors to numerous opportunities in metalworking.